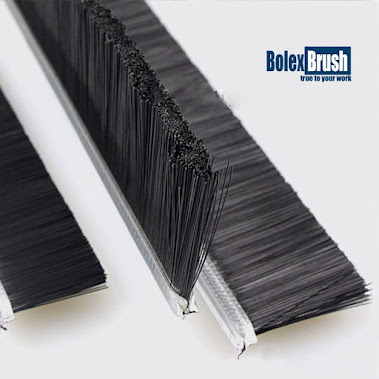

Strip Brushes– Suitable For Cleaning Various Surfaces

Maintaining hygiene and preventing contamination are top priorities in the food processing and packaging industries. The brushes play a vital role in ensuring cleanliness and product integrity in these environments. They are used in food processing equipment for cleaning conveyors, sorting lines, and packaging machinery, removing debris and residues to maintain sanitation standards. The strip brushes also find application in sealing gaps and preventing product spillage during packaging processes. Escalators and elevators require regular maintenance to ensure safe and efficient operation. Strip brushes play a crucial role in these maintenance procedures by providing safety features. Mounted along the edges of escalator steps and elevator doors, strip brushes act as safety brushes, preventing entrapment of fingers, clothing, or other objects. By creating a barrier between moving parts and passengers, strip brushes contribute to the overall safety of these transportation systems. Stri